By: Roger Kremer and Tom Fabrizio

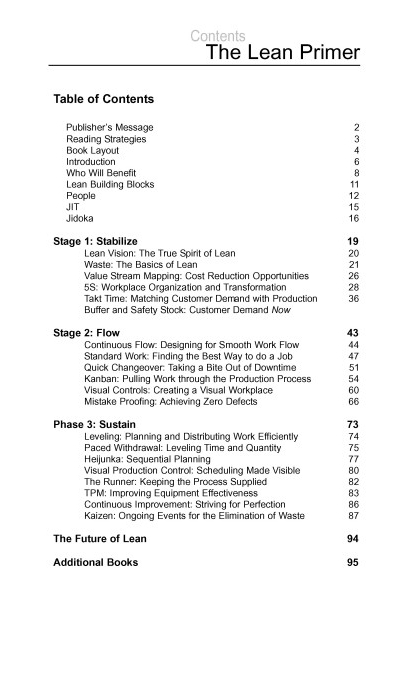

The Lean Primer will allow you to train the organization to understand how critical the implementation of Lean principles and processes are to your short and long term success. It will provide the various reasons why an organization must go Lean, as well as detailing what Lean is. Lean will be explained in the terms of Stabilize, Flow, and Sustain with reference to the following topics of lean vision, waste, value stream mapping, 5S, takt time, buffer and safety stock, continuous flow, standard work, quick changeover, kanban, visual controls, mistake-proofing, leveling, paced withdrawal, visual production control, runners, TPM, and kaizen. Each of these tools will also be explained with digital photos from world-class shops from across the US that shared their best practices.

About The Lean Primer

No matter the size of the organization, from the prototype job shop of 3 persons to the larger Fortune 500 companies with thousands of employees at one location – and every type of manufacturing industry between – all have one thing in common – their need to continually communicate effectively and efficiently to employees, whatever the subject may be. The Lean Primer was created to be the communication platform that will allow all levels of the organization to gain the basic knowledge required to more fully accept and contribute to Lean initiatives.

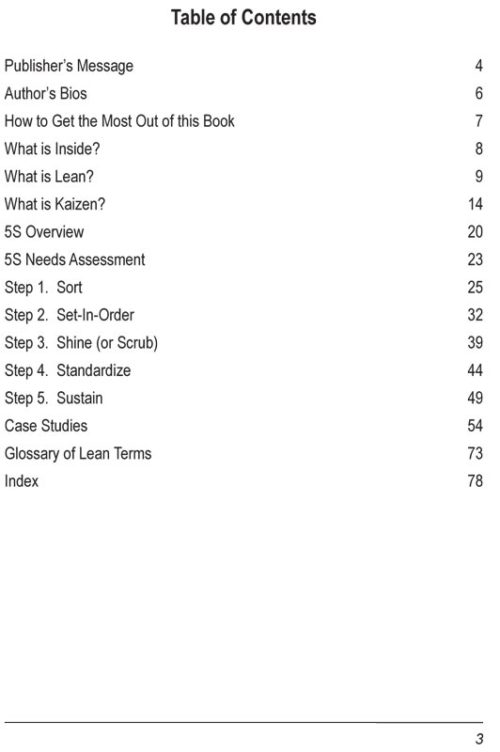

The Lean Primer allows for a brief description of 5S, Takt Time, Buffer and Safety Resources, Value Stream Mapping, Visual Controls plus many other of the Lean tools, followed by practical applications of those tools being used. It provides the relevant information that should be used to train an organization what Lean is and why go Lean.

The Lean Primer has the following features:

- Identify and eliminate process waste and variation quickly and efficiently in any production environment.

- Increase participation and communication at all levels of the organization.

- Standardize best processes as the basis for improvement.

- Create a favorable Lean environment so that a continuous improvement culture will evolve.

Testimonials:

“The Lean Primer gave me insight into what Lean tools would assist us the most in our cost reduction initiatives. The book was well done in explaining the tools in job shop terminology.” Raymond Page, VP Operations, GAP Manufacturing, Inc.

“Excellent! Now I understand a simple approach to implementing Lean. This book provided real examples with good, brief definitions. A great reference book on Lean tools for the small shop or for any other shop for that matter.” Bill Hubbard, Plant Manager, Erie Products, Inc.

“I passed this out to my managers and supervisors to read. After a few days we all had the same language to discuss Lean and how to move forward……thanks!” Joe Normandy, Hammond Manufacturing and Assembly, Inc.

Perfect Bound – 7” x 10” – 96 pages, 50+ Plant Photos

Reviews

There are no reviews yet.