By: Rob Ptacek and Jaideep Motwani (Ph.D.)

The Lean Six Sigma Training Set is your complete set of materials for conducting training on the tools and concepts of Lean and Six Sigma. With over 300+ PowerPoint slides, each tool is thoroughly explained with examples from a wide range of industries as well as administrative and desktop processes. Use this Training Set to customize and add/remove examples and photos as you deem appropriate. No training program that is purchased can be exactly what you want, therefore, it is expected this set be customized.

Included in this Training Set are the following items:

– 1 – Facilitator’s Guide that has the detailed Instructor Notes referencing The Lean Six Sigma Pocket Guide XL and Pursuing Perfect Service books

– 1 – CD that contains the PowerPoint presentation, simulation, Jeopardy Game, and exercises

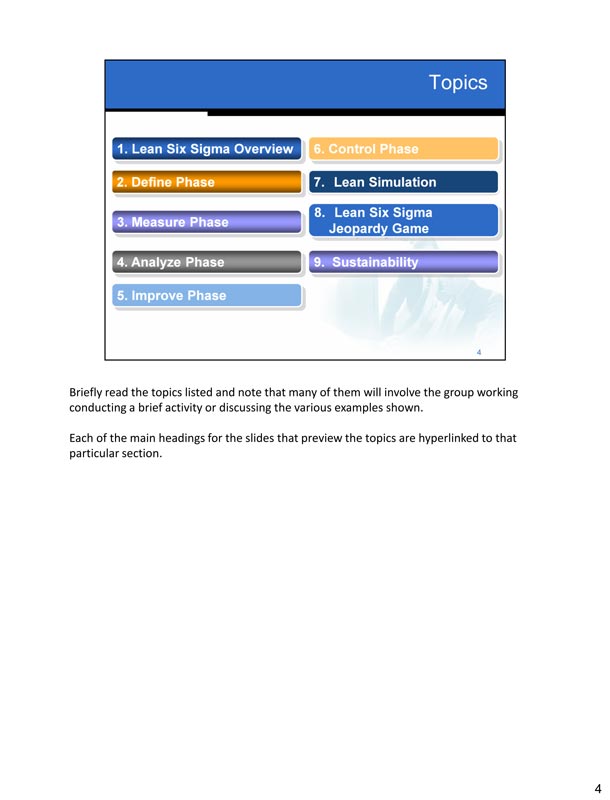

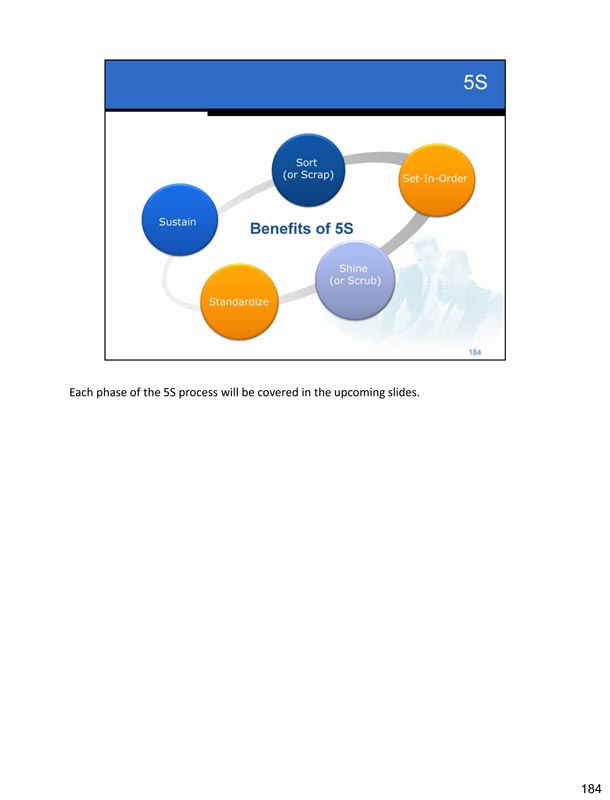

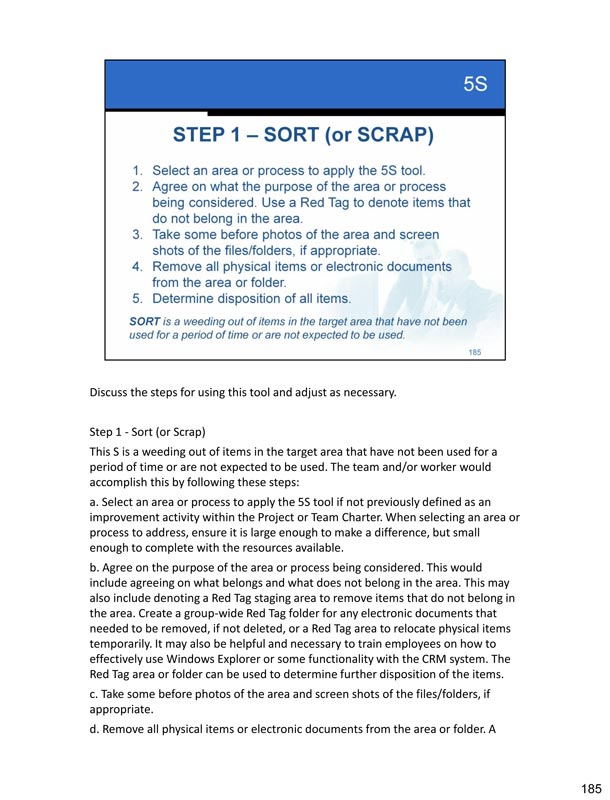

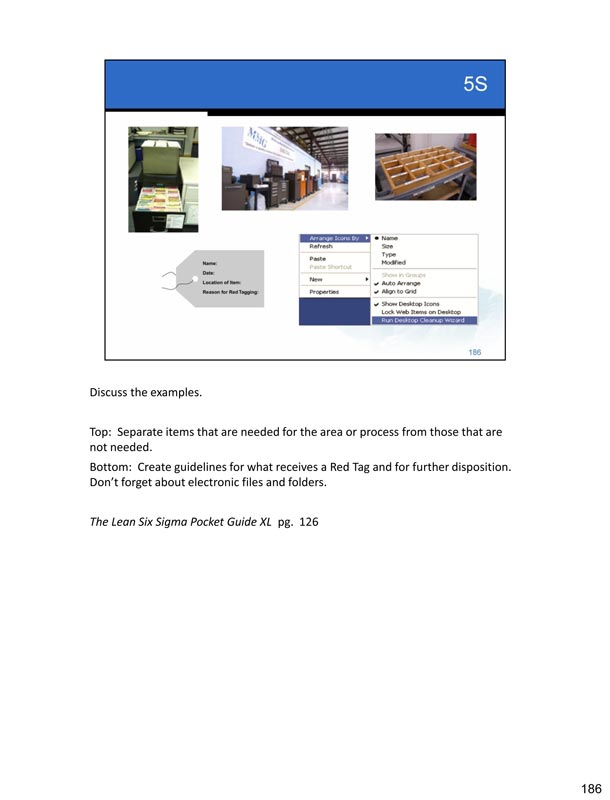

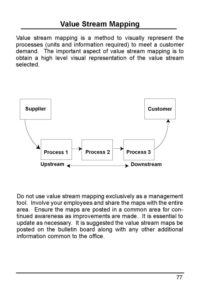

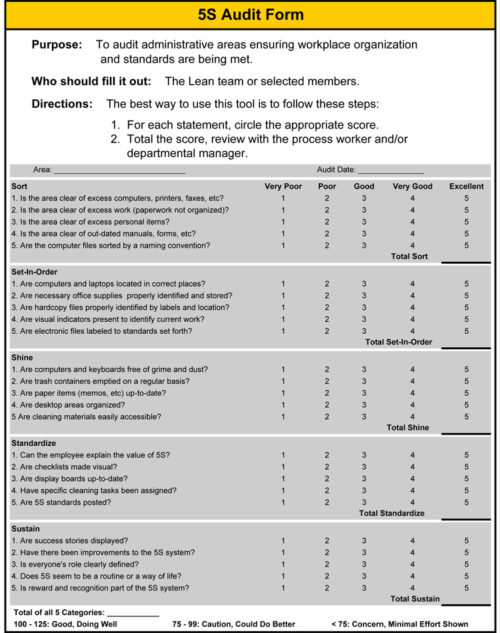

The various tools within the D-M-A-I-C methodology are explained in the Training Set as follows: The Define Phase of Performance Dashboards, Project Charter, Teaming, Effective Meetings, Team Charter, Project Planner (PP), Action Item (AI) Log, Issues and Opportunities (IO) Log; The Measure Phase of Voice of the Customer (VOC, Quality Function Deployment (QFD), Value Stream and Process Maps, Supplier-Input-Process-Output-Customer (SIPOC) Diagrams, Key Metric and Data Profile, Check Sheets and Frequency Charts, Run Charts, Measurement System Analysis (MSA); The Analyze Phase of Value-Added (VA) versus Non Value-Added (NVA) Analysis, Pareto and Pie Charts, Constraint or Bottleneck Analysis, Demand Analysis Plots and Takt Time, Histograms, Ogive Charts, and Cumulative Frequency, Cause and Effect (or Fishbone) Diagrams, Brainstorming, 5 Whys, Radar Charts, Scatter Plots, Process Capability, Force Field Analysis, Interrelationship Diagrams, Impact Maps, Employee Balance Charts; The Improve Phase of Rapid Improvement Events, Plan-Do-Check-Act (PDCA) Process, 5S, Visual Controls, Mistake Proofing, Standard Work, Process or Work Area Layout, Mass Customization, Flow, Quick Changeovers (QCO), Total Productive Maintenance (TPM), Cross-Training; The Control Phase of Project Management, Statistical Process Control (SPC) , Visual Management, Standard Work for Leaders, Performance Management, Problem Solving – Corrective and Preventative Actions, Layered Process Audits (LPA). The Appendix contains Sustainability (or Becoming Green), Waste Walk, Glossary, and Index.

Don’t go Lean Sigma without this valuable training tool!

Reviews

There are no reviews yet.