By: Jayant Trewn, PhD, Todd Sperl, Rob Ptacek, and Deborah Salimi, PhD

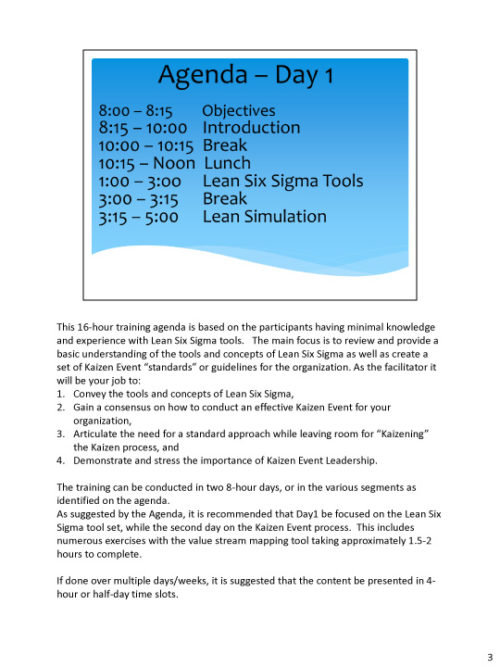

The Kaizen Event Training package is your comprehensive set of materials to facilitate the training of those within your organization responsible for implementing continuous improvement projects (i.e., Kaizen Events). Five types of Kaizen Events will be detailed allowing teams to conduct full 5-day type events to conveying approaches on how individuals can contribute via kaizen in improving daily processes. The five types of Kaizen Events are: Standard 5 Day Kaizen Event, Rolling Kaizen Event, Web Based Kaizen Event, Today's Kaizen Event, and Wiki (or Quick) Kaizen Event. The materials are based on the best selling book, Kaizen Demystified which was written by authors/consultants with having conducted over 1,000 Kaizen Events! The training is for Black or Green Belts, Continuous Improvement Specialists, Lean Senseis, departmental supervisors and managers, work group or team leaders, etc. - basically, anyone that has someone reporting to them and is responsible for improving processes. Or, it can be used for Green Belt training or for those individuals who have little or no experience with Lean Six Sigma.

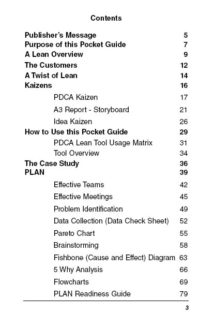

Lean and problem solving applies to all stages of the design-bid-build construction project. It is all about conveying the Plan-Do-Check-Act (PDCA) cycle of problem solving with a long term Lean focus. The unique problems of the construction industry can be solved by using many of the tools and concepts of Lean and Six Sigma.

-

Sale!

The Lean Desktop Application Assessment allows an individual or group to evaluate current information and data flow relative to Lean concepts and tools. The Assessment is a customizable Microsoft Excel spreadsheet that will serve as a baseline as improvements are made over time, The Lean Desktop Application Assessment should take 5 - 10 minutes for an individual to complete and 30 - 45 minutes for a work group to complete (fill out, not create). Subsequent analysis for the work group may require an additional 1 - 2 hours to plan their first Lean Desktop project from the results of the assessment. The Assessment has 10 main categories that are each linked to an Instruction Sheet that details that particular category as well as to the Overview Sheet (Radar Chart). The score will assist you into allocating the appropriate resources in your Lean Desktop project. The Assessment has 10 main categories of 5S, Quality, Document Management, Visual Controls, Standard Work, Continuous Flow, Email, Leveling, Continuous Improvement, and Digital Waste Training, as well as 34 sub-categories.

The Lean Desktop Application Assessment allows an individual or group to evaluate current information and data flow relative to Lean concepts and tools. The Assessment is a customizable Microsoft Excel spreadsheet that will serve as a baseline as improvements are made over time, The Lean Desktop Application Assessment should take 5 - 10 minutes for an individual to complete and 30 - 45 minutes for a work group to complete (fill out, not create). Subsequent analysis for the work group may require an additional 1 - 2 hours to plan their first Lean Desktop project from the results of the assessment. The Assessment has 10 main categories that are each linked to an Instruction Sheet that details that particular category as well as to the Overview Sheet (Radar Chart). The score will assist you into allocating the appropriate resources in your Lean Desktop project. The Assessment has 10 main categories of 5S, Quality, Document Management, Visual Controls, Standard Work, Continuous Flow, Email, Leveling, Continuous Improvement, and Digital Waste Training, as well as 34 sub-categories. -

Sale!

The Lean Office Assessment was created allowing a departmental work group or individual to continually assess their Lean or continuous improvement initiatives. The Lean Office Assessment is a customizable Microsoft Excel spreadsheet that will provide a baseline from which you can then improve your administrative processes. It also can assist in determining which Lean tools may be of value during a continuous improvement project. The Lean Office Assessment has 10 Lean building block categories that are further divided into 34 sub-categories that are individually scored. All categories are automatically linked to the Overview page which displays a Radar (or Spider) Chart of the total category scores. The score will assist you into allocating the appropriate resources in your Lean project. When conducting the Assessment the work group or individual must relate their database management procedures and Microsoft Office practices to the overall concepts and tools referenced. The 10 categories are: 5S, Quality, Physical Layout, Visual Controls, Standard Work, Continuous Flow, Pull Systems, Leveling, Continuous Improvement, and Training.

The Lean Office Assessment was created allowing a departmental work group or individual to continually assess their Lean or continuous improvement initiatives. The Lean Office Assessment is a customizable Microsoft Excel spreadsheet that will provide a baseline from which you can then improve your administrative processes. It also can assist in determining which Lean tools may be of value during a continuous improvement project. The Lean Office Assessment has 10 Lean building block categories that are further divided into 34 sub-categories that are individually scored. All categories are automatically linked to the Overview page which displays a Radar (or Spider) Chart of the total category scores. The score will assist you into allocating the appropriate resources in your Lean project. When conducting the Assessment the work group or individual must relate their database management procedures and Microsoft Office practices to the overall concepts and tools referenced. The 10 categories are: 5S, Quality, Physical Layout, Visual Controls, Standard Work, Continuous Flow, Pull Systems, Leveling, Continuous Improvement, and Training. -

Sale!

Work load balancing is the optimal distribution of work units throughout the value stream to maintain takt time or pitch. Also known as employee/staff balancing or line balancing, work load balancing assures that now one worker is doing too much or too little work. Work load balancing begins with analyzing the current state of how work relative to the value stream is allocated and ends with an even and fair distribution of work, ensuring that customer demand is met with a continuous flow mentality. The Employee Balance eTool will make this process easier by allowing you to enter the various process activities and cycle times, as well as automatically displaying them in bar graph form. This eTool is a fully customizable Microsoft Excel file. Everything is here and ready for you to get started!

Work load balancing is the optimal distribution of work units throughout the value stream to maintain takt time or pitch. Also known as employee/staff balancing or line balancing, work load balancing assures that now one worker is doing too much or too little work. Work load balancing begins with analyzing the current state of how work relative to the value stream is allocated and ends with an even and fair distribution of work, ensuring that customer demand is met with a continuous flow mentality. The Employee Balance eTool will make this process easier by allowing you to enter the various process activities and cycle times, as well as automatically displaying them in bar graph form. This eTool is a fully customizable Microsoft Excel file. Everything is here and ready for you to get started! -

By: Jayant Twewn (PhD), Todd Sperl, Rob Ptacek, and Deborah Salimi (PhD)

By: Jayant Twewn (PhD), Todd Sperl, Rob Ptacek, and Deborah Salimi (PhD)

We are pleased to present Kaizen Demystified, perfectly timed for today s ever-changing and ever-demanding business environment requiring improved processes. Whether your industry is manufacturing, healthcare, financial, education, armed forces, services, government, or the construction industry, or, you are a manager, supervisor, team leader, or a front-line worker, this book will provide new insights and ideas for managing and facilitating continuous improvement and problem solving projects (i.e., Kaizen Events). Kaizen Demystified provides a simple and practical approach detailing five distinct methods on how Lean (and Six Sigma) tools and concepts can quickly and efficiently be applied and managed to solve business problems and improve processes. The five types of Kaizen Events detailed in this book are the: (1) Standard 5 Day Kaizen Event, also referred to as a Kaizen Blitz or Rapid Improvement Event, (2) Rolling Kaizen Event, (3) Web Based Kaizen Event, (4) Today's Kaizen Event, and (5) Wiki (or Quick) Kaizen Event. Each type will be thoroughly explained to demystify what it may mean for you. Kaizen Event Leadership is thoroughly explored in a separate chapter/section that relates to all types of Kaizen Events. It provides a listing of the common issues facing the leader of a Kaizen Event as well as suggested how-to leadership skills to address those issues. This is one of the most important aspects of leading any type of Kaizen Event. -

By: Rob Ptacek, Mark Coats, Col. (Retired, US Army), Todd PtacekToday's Lean Leader is designed for use as a quick and convenient reference, or as a training guide to improve your effectiveness in leading, supervising, and coaching employees. It provides valuable insight into the How To's of leadership and supervision. Today's Lean Leader can be used in a variety of ways, some of which are: (1)The guide is valuable for the new or veteran leader - supervisor (2) Remarkably, the guide in the hands of the workforce makes the task of leading and supervising all the easier when everyone is on the same page on these basic principles.

By: Rob Ptacek, Mark Coats, Col. (Retired, US Army), Todd PtacekToday's Lean Leader is designed for use as a quick and convenient reference, or as a training guide to improve your effectiveness in leading, supervising, and coaching employees. It provides valuable insight into the How To's of leadership and supervision. Today's Lean Leader can be used in a variety of ways, some of which are: (1)The guide is valuable for the new or veteran leader - supervisor (2) Remarkably, the guide in the hands of the workforce makes the task of leading and supervising all the easier when everyone is on the same page on these basic principles. -

Sale!

The Kaizen Demystified Worksheets allow you to customize the tools, concepts, practices, and worksheets demonstrated in the Kaizen Demystified book. These 46 electronic worksheets will allow for an effective and efficient application of engaging people in a Kaizen Event. Delivered as customizable Excel worksheets.

The Kaizen Demystified Worksheets allow you to customize the tools, concepts, practices, and worksheets demonstrated in the Kaizen Demystified book. These 46 electronic worksheets will allow for an effective and efficient application of engaging people in a Kaizen Event. Delivered as customizable Excel worksheets. -

By: Rob Ptacek, Todd Sperl, and Jayant Trewn (PhD) The Practical Lean Six Sigma Pocket Guide is designed as a convenient, quick reference, and, most importantly, a step-by-step implementation guide. You can put your finger on any tool within a matter of seconds! Find the right tool for the right initiative by using the: - Navigate the Prepare - Define - Measure - Analyze - Improve - Control right side book tabs. - Complete the A3 Project Report as you learn and apply the various tools on the project by:

By: Rob Ptacek, Todd Sperl, and Jayant Trewn (PhD) The Practical Lean Six Sigma Pocket Guide is designed as a convenient, quick reference, and, most importantly, a step-by-step implementation guide. You can put your finger on any tool within a matter of seconds! Find the right tool for the right initiative by using the: - Navigate the Prepare - Define - Measure - Analyze - Improve - Control right side book tabs. - Complete the A3 Project Report as you learn and apply the various tools on the project by:- Go to the tab in the book that corresponds to the D-M-A-I-C Phase you are working on.

- Read about the tools for that phase of your project.

- Apply the appropriate tools.

- Complete the relevant section of the A3 Project Report.

- Repeat 1 - 4 as you navigate through the phases and complete your project.

-

First of its kind! The Simply Lean Pocket Guide for Construction is the integration of Lean and the PDCA methodology. The actual case study of Midway Construction demonstrates specifically how problem solving and Lean were used in achieving significant results involving various aspects of the construction industry. The case study - along with the detailed descriptions of the quality improvement tools (with a Lean twist as explained in the case) allows you to take your organization to your next performance level.

First of its kind! The Simply Lean Pocket Guide for Construction is the integration of Lean and the PDCA methodology. The actual case study of Midway Construction demonstrates specifically how problem solving and Lean were used in achieving significant results involving various aspects of the construction industry. The case study - along with the detailed descriptions of the quality improvement tools (with a Lean twist as explained in the case) allows you to take your organization to your next performance level.

NOTE: We are only providing this book as Print On Demand (POD) which requires a minimum order of 100 books. Please call 734-475-4301 to place your order. If you require less than that, please consider The New and Improved Lean Office Pocket Guide or The Simple Lean Pocket Guide.

-

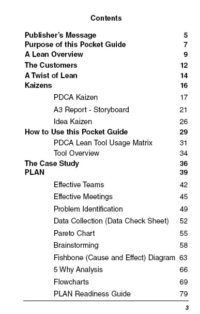

First of its kind! The Simply Lean Pocket Guide is the integration of Lean and the PDCA methodology. The interactive Tinker Town case study allows you to take problem solving with a Lean twist to your next performance level. The most basic premise of Lean is to simply and effectively problem solve. The Simply Lean Pocket Guide is a step-by-step approach to the implementation of process improvements using the PDCA model along with a Lean twist. If you are just beginning to adopt Lean or Six Sigma as a business improvement model, whether you are in the healthcare, financial services, construction, armed services, manufacturing, government, logistics, service, or construction industry, the first thing that should be acknowledged is that the solution to the problem (or improvement target that is to be reached) will be found in the intellect of the people who are working the process. Therefore, as a trainer, consultant (internal or external), or departmental head, the focus to improve a situation would be to “somehow” work with that group (and their intellect) and find a solution. However, that “somehow” is not always easy to attain and will require some guidance along the way.

First of its kind! The Simply Lean Pocket Guide is the integration of Lean and the PDCA methodology. The interactive Tinker Town case study allows you to take problem solving with a Lean twist to your next performance level. The most basic premise of Lean is to simply and effectively problem solve. The Simply Lean Pocket Guide is a step-by-step approach to the implementation of process improvements using the PDCA model along with a Lean twist. If you are just beginning to adopt Lean or Six Sigma as a business improvement model, whether you are in the healthcare, financial services, construction, armed services, manufacturing, government, logistics, service, or construction industry, the first thing that should be acknowledged is that the solution to the problem (or improvement target that is to be reached) will be found in the intellect of the people who are working the process. Therefore, as a trainer, consultant (internal or external), or departmental head, the focus to improve a situation would be to “somehow” work with that group (and their intellect) and find a solution. However, that “somehow” is not always easy to attain and will require some guidance along the way. -

First of its kind! The Simply Lean Pocket Guide is the integration of Lean and the PDCA methodology. The interactive Tinker Town case study allows you to take problem solving with a Lean twist to your next performance level. The most basic premise of Lean is to simply and effectively problem solve. The Simply Lean Pocket Guide is a step-by-step approach to the implementation of process improvements using the PDCA model along with a Lean twist. If you are just beginning to adopt Lean or Six Sigma as a business improvement model, whether you are in the healthcare, financial services, construction, armed services, manufacturing, government, logistics, service, or construction industry, the first thing that should be acknowledged is that the solution to the problem (or improvement target that is to be reached) will be found in the intellect of the people who are working the process. Therefore, as a trainer, consultant (internal or external), or departmental head, the focus to improve a situation would be to “somehow” work with that group (and their intellect) and find a solution. However, that “somehow” is not always easy to attain and will require some guidance along the way. Simply Lean will provide that guidance ensuring root causes and wastes are eliminated in creating a Leaner, problem-free process.

First of its kind! The Simply Lean Pocket Guide is the integration of Lean and the PDCA methodology. The interactive Tinker Town case study allows you to take problem solving with a Lean twist to your next performance level. The most basic premise of Lean is to simply and effectively problem solve. The Simply Lean Pocket Guide is a step-by-step approach to the implementation of process improvements using the PDCA model along with a Lean twist. If you are just beginning to adopt Lean or Six Sigma as a business improvement model, whether you are in the healthcare, financial services, construction, armed services, manufacturing, government, logistics, service, or construction industry, the first thing that should be acknowledged is that the solution to the problem (or improvement target that is to be reached) will be found in the intellect of the people who are working the process. Therefore, as a trainer, consultant (internal or external), or departmental head, the focus to improve a situation would be to “somehow” work with that group (and their intellect) and find a solution. However, that “somehow” is not always easy to attain and will require some guidance along the way. Simply Lean will provide that guidance ensuring root causes and wastes are eliminated in creating a Leaner, problem-free process. -

Sale!

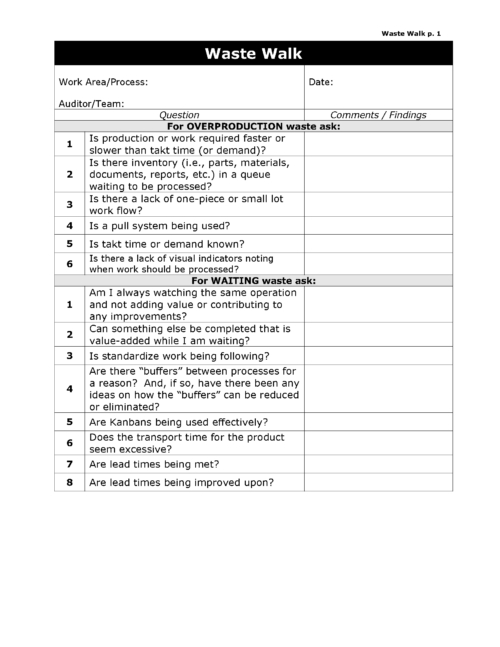

A Waste Walk is an activity for project team members to further understand a process area that is being considered for improvement, asking questions, and then identifying the wastes on the current state value stream or process map. Using this customizable Waste Walk Audit form, the team members, along with their Lean training, can view the area with a fresh perspective as they identify process waste. Delivered as customizable Word document.

A Waste Walk is an activity for project team members to further understand a process area that is being considered for improvement, asking questions, and then identifying the wastes on the current state value stream or process map. Using this customizable Waste Walk Audit form, the team members, along with their Lean training, can view the area with a fresh perspective as they identify process waste. Delivered as customizable Word document.