-

By: Rob Ptacek and Jaideep Motwani (Ph.D.)

By: Rob Ptacek and Jaideep Motwani (Ph.D.)

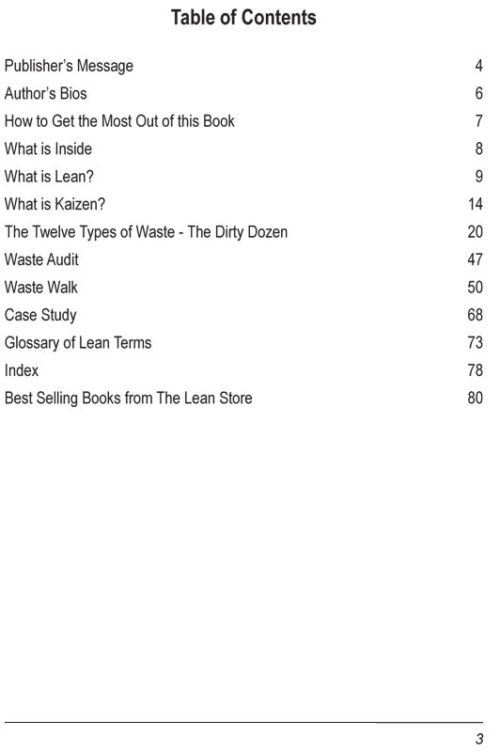

Today’s Lean! Learning About and Identifying Waste is the first book from the Today’s Lean! series published by MCS Media, Inc. It has been suggested by you, our readers, that you would like Lean and Six Sigma information to be more succinct and at your fingertips, thus allowing for a single tool or concept to be easily accessible (i.e., as a pocket guide and not a manual). Therefore, the Today’s Lean! series of books provide:- Concise content on one main Lean or Six Sigma tool or concept

- Numerous case studies, worksheets, and examples from all types of industries

- Availability as a pocket guide or ebook

- A standard format

- An avenue to update content immediately via your feedback and input (via ebook updates)

- An inspiration for you to implement something similar

-

Sale!

By: Roger Kremer and Tom Fabrizio The Lean Primer will allow you to train the organization to understand how critical the implementation of Lean principles and processes are to your short and long term success. It will provide the various reasons why an organization must go Lean, as well as detailing what Lean is. Lean will be explained in the terms of Stabilize, Flow, and Sustain with reference to the following topics of lean vision, waste, value stream mapping, 5S, takt time, buffer and safety stock, continuous flow, standard work, quick changeover, kanban, visual controls, mistake-proofing, leveling, paced withdrawal, visual production control, runners, TPM, and kaizen. Each of these tools will also be explained with digital photos from world-class shops from across the US that shared their best practices.

By: Roger Kremer and Tom Fabrizio The Lean Primer will allow you to train the organization to understand how critical the implementation of Lean principles and processes are to your short and long term success. It will provide the various reasons why an organization must go Lean, as well as detailing what Lean is. Lean will be explained in the terms of Stabilize, Flow, and Sustain with reference to the following topics of lean vision, waste, value stream mapping, 5S, takt time, buffer and safety stock, continuous flow, standard work, quick changeover, kanban, visual controls, mistake-proofing, leveling, paced withdrawal, visual production control, runners, TPM, and kaizen. Each of these tools will also be explained with digital photos from world-class shops from across the US that shared their best practices. -

By: Roger Kremer

By: Roger Kremer

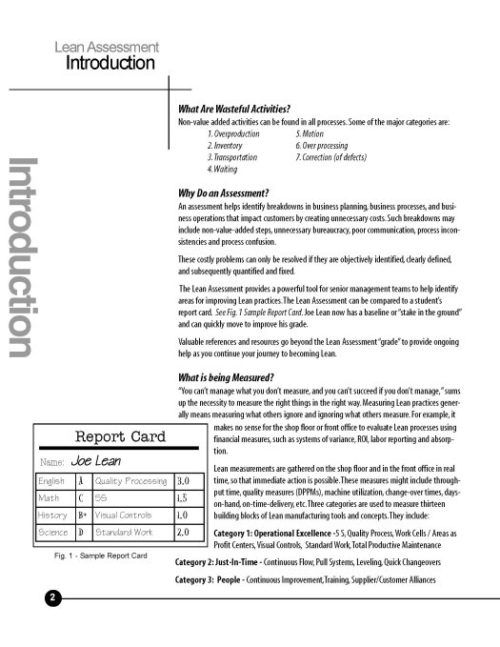

The Lean Assessment was created as a guide to allow the job shop and small manufacturer in their Lean journey. The Lean Assessment will provide a baseline upon which you can improve - and most importantly also provide a reference on what to do. The Lean Assessment has 13 Lean building block categories that are further divided into sub-categories that are scored. The subsequent score will assist you into allocating the appropriate resources in your Lean project. Administrative areas are also referenced in this assessment. The Assessment is self-administering and will allow you to create the necessary visual spider chart to convey the score within the organization. -

By: Roger Kremer

By: Roger Kremer

The Lean Office Pocket Handbookis a quick-reference guide covering the terms, concepts, benefits and techniques for the application of Lean in administrative areas of all industry types. It is easy to follow, simple in its concepts, and, above all, practical to use. The tools of 5S, continuous flow, office layout, value stream mapping, process mapping, problem solving, kanbanning office supplies, kaizen, plus numerous other Lean tools are defined in terms that relate to the administrative environment. -

By: Luz Planco Cuando implemente la oficina esbelta, debe tener en cuenta que la implementaci n es una traves a cuando piense que ha llegado al final descubrir que habr n mucho m s "optimizaciones cont nuas" y cuando piense que alcanz la meta a n quedar n m s optimizaciones cont nuas por realizar. La meta final esbelta es la creaci n de una cultura de optimizaci n cont nua de cada d a, en todos los productos y servicios, por todo el personal. Una vez que usted tenga esto establecido, las herramientas esbeltas emerger n como palabras diarias, tales como 5S, kaizen y kanban.

By: Luz Planco Cuando implemente la oficina esbelta, debe tener en cuenta que la implementaci n es una traves a cuando piense que ha llegado al final descubrir que habr n mucho m s "optimizaciones cont nuas" y cuando piense que alcanz la meta a n quedar n m s optimizaciones cont nuas por realizar. La meta final esbelta es la creaci n de una cultura de optimizaci n cont nua de cada d a, en todos los productos y servicios, por todo el personal. Una vez que usted tenga esto establecido, las herramientas esbeltas emerger n como palabras diarias, tales como 5S, kaizen y kanban. -

Sale!

By: Luz Blanco Palma The New Lean Pocket Guide (en Espanól) La Nueva Lean de Bolsillo (Produccion Lean) Refuerze la transformación hacia los procesos esbeltos con La Nueva Guía de Bolsillo (Lean Producción). Este manual ha sido desarrollado tanto para directivos como para empleados, gráficamente explícito, sirve de referencia rápida sobre los procesos de manufacturación esbelta y está optimizado para reducir costos, optimizar la calidad, entregar los productos a tiempo y proveerlo con los conocimientos necesarios para seguir siendo ¡globalmente competitivo en el siglo 21! Esta guía está diseñada para usarla como referencia conveniente y rápida mientras se aprende a implementar la manufactura, tecnología y herramientas esbeltas. Este manual provee de una valiosa visión de los matices del proceso esbelto o lean. ¡Se tiene a mano cualquier aspecto del proceso esbelto en segundos! Y está definitivamente enfocado a las industrias manufactureras. El objetivo principal de esta La Nueva Guía de Bolsillo (Producción Lean) es informar sobre cómo las herramientas de procesos esbeltos pueden ser utilizadas para eliminar cargas y trabajo descartable. Cuanto mejor definido, analizado y resueltos los desperdicios, mejor sera la utilización de estas herramientas en la secuencia apropiada de implementación; por ende mejor será el recorrido del camino hacia la esbeltez globalizada. Indice de Materias - Matriz de Herramientas para Procesos Esbeltos, 5 Eses, Análisis de la Cantidad de Producto (CP) y del Desperdicios y Cargas Descartables, Existencias Acumuladas y de Reserva, Visual, Flujo Continuo, Heijunka (Nivelación de la Carga de Trabajo), Informes y Comunicaciones Esbeltas, Intercambio Rápido, Jidoka, Justo-A-Tiempo, Kanban (Sistema de Arrastre), Layout Celular: Forma de U, Manejo de Herramientas Perecederas, Manejo del la Cadena de Producción, Mantención del Total Productivo, Mapeo de la Cadena de Producción, Metodología para Resolución de Problemas, Métricas de Procesos Esbeltos, Nivelación de la Línea de Producción, Oficina Esbelta (Lean Office), Organigrama, Origen del Proceso Esbelto, Prueba de Errores, Responsable de la Producción, Retiro Pausado, Secuencia para la Implementación del Proceso Esbelto, Seis Sigma (Six Sigma),Talleres Kaizen, Tiempo Cíclico, Tiempo de Ejecución Taka, Tiempo de Retiro del Producto Empacado, Trabajo Estándar, Auditoría de Desperdicios y de Cargas, Glosario.

By: Luz Blanco Palma The New Lean Pocket Guide (en Espanól) La Nueva Lean de Bolsillo (Produccion Lean) Refuerze la transformación hacia los procesos esbeltos con La Nueva Guía de Bolsillo (Lean Producción). Este manual ha sido desarrollado tanto para directivos como para empleados, gráficamente explícito, sirve de referencia rápida sobre los procesos de manufacturación esbelta y está optimizado para reducir costos, optimizar la calidad, entregar los productos a tiempo y proveerlo con los conocimientos necesarios para seguir siendo ¡globalmente competitivo en el siglo 21! Esta guía está diseñada para usarla como referencia conveniente y rápida mientras se aprende a implementar la manufactura, tecnología y herramientas esbeltas. Este manual provee de una valiosa visión de los matices del proceso esbelto o lean. ¡Se tiene a mano cualquier aspecto del proceso esbelto en segundos! Y está definitivamente enfocado a las industrias manufactureras. El objetivo principal de esta La Nueva Guía de Bolsillo (Producción Lean) es informar sobre cómo las herramientas de procesos esbeltos pueden ser utilizadas para eliminar cargas y trabajo descartable. Cuanto mejor definido, analizado y resueltos los desperdicios, mejor sera la utilización de estas herramientas en la secuencia apropiada de implementación; por ende mejor será el recorrido del camino hacia la esbeltez globalizada. Indice de Materias - Matriz de Herramientas para Procesos Esbeltos, 5 Eses, Análisis de la Cantidad de Producto (CP) y del Desperdicios y Cargas Descartables, Existencias Acumuladas y de Reserva, Visual, Flujo Continuo, Heijunka (Nivelación de la Carga de Trabajo), Informes y Comunicaciones Esbeltas, Intercambio Rápido, Jidoka, Justo-A-Tiempo, Kanban (Sistema de Arrastre), Layout Celular: Forma de U, Manejo de Herramientas Perecederas, Manejo del la Cadena de Producción, Mantención del Total Productivo, Mapeo de la Cadena de Producción, Metodología para Resolución de Problemas, Métricas de Procesos Esbeltos, Nivelación de la Línea de Producción, Oficina Esbelta (Lean Office), Organigrama, Origen del Proceso Esbelto, Prueba de Errores, Responsable de la Producción, Retiro Pausado, Secuencia para la Implementación del Proceso Esbelto, Seis Sigma (Six Sigma),Talleres Kaizen, Tiempo Cíclico, Tiempo de Ejecución Taka, Tiempo de Retiro del Producto Empacado, Trabajo Estándar, Auditoría de Desperdicios y de Cargas, Glosario. -

Sale!

By: Don Tapping, Sue Kozlowski, Laura Archbold, and Todd SperlValue Stream Management (VSM) is a proven and effective step-by-step methodology for understanding and applying the principles and practices of the Toyota Production System (i.e., Lean) within a healthcare organization. As authors, we have found continued success in applying the Value Stream Management methodology in the hospitals, clinics, and labs. You will be introduced to many of these successes throughout the book as topical anecdotes. The specific tools and practices of Lean and the implementation plan via the Value Stream Management process will be thoroughly explained.

By: Don Tapping, Sue Kozlowski, Laura Archbold, and Todd SperlValue Stream Management (VSM) is a proven and effective step-by-step methodology for understanding and applying the principles and practices of the Toyota Production System (i.e., Lean) within a healthcare organization. As authors, we have found continued success in applying the Value Stream Management methodology in the hospitals, clinics, and labs. You will be introduced to many of these successes throughout the book as topical anecdotes. The specific tools and practices of Lean and the implementation plan via the Value Stream Management process will be thoroughly explained. -

Sale!

By: Don Tapping and John West

By: Don Tapping and John West

Who Hollered Fore? creates an awareness of the evils of variation – along with the realization of what that costs an organization in time and money. This book will assist in creating a common language and basic Lean theme throughout your organization. Through the story of John, Laura, and the Bartlett’s, as they participate in a charity golf event, the conversation about Lean and golf become intertwined. And finally they discover the secret to it all! About Who Hollered Fore? Who Hollered Fore? creates an awareness of the evils of variation – along with the realization of what that costs an organization in time and money. It also provides a common language and theme so everyone can understand its importance. This realization and subsequent action will dramatically improve an organization’s ability to improve the current process – thereby improving the bottom-line. -

By: Don Tapping

By: Don Tapping

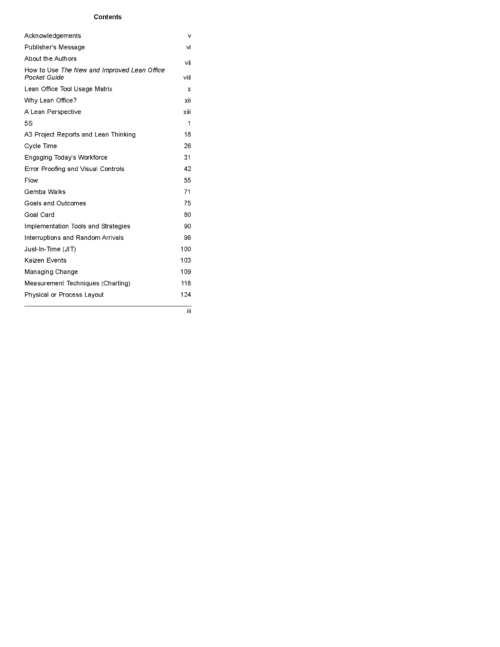

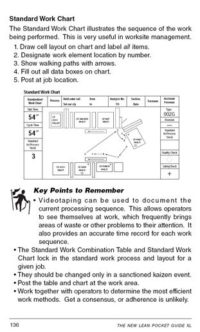

Note: Discontinued! If this product is ordered we will substitute the more comprehensive and up-to-date Practical Lean Six Sigma for Offices (value of $12.95 and is the larger 5" x 8.5" format for easier reading) for the same price for a limited time only. (If quantities over 100 are needed, we can Print-on-Demand, and please email info@theleanstore.com for pricing and availability.)The New and Improved Lean Office Pocket Guide has over 120 illustrations to visually convey the tools and concepts, along with detailed descriptions of all the Lean tools. This newer version of the best selling The Lean Office Pocket Guide also includes: 10 sections that include examples of Lean for electronic files and folders, a Waste Audit, and a Glossary of Lean terms. The tools of 5S, value stream mapping, document tagging, continuous flow, standard work, visual control, takt time, pitch, runners, waste, plus numerous other Lean tools are thoroughly defined as well as guidelines provided for the implementation of each tool. This version has digital photos of Lean office best practices throughout! -

By: Don Tapping

By: Don Tapping

The New Lean Pocket Guide has over 120 illustrations to visually convey the tools and concepts, along with detailed descriptions of all the Lean tools. This newer version of the best selling The Lean Pocket Guide also includes: a section on Lean Office and Six Sigma, 20+ digital photos demonstrating Lean in action, a Waste Audit, and a Glossary of Lean terms. The tools of 5S, value stream mapping, document tagging, continuous flow, standard work, visual control, takt time, pitch, runners, waste, plus numerous other Lean tools are thoroughly defined as well as guidelines provided for the implementation of each tool. This version has digital photos of Lean production best practices throughout! -

Sale!

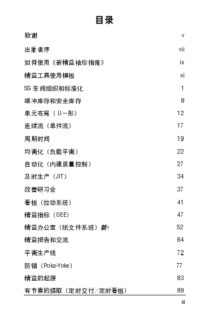

By: Don Tapping The New Lean Pocket Guide (Chinese Edition) has over 120 illustrations to visually convey the tools and concepts, along with detailed descriptions of all the Lean tools. This newer version of the best selling The Lean Pocket Guide also includes: a section on Lean Office and Six Sigma, 20+ digital photos demonstrating Lean in action, a Waste Audit, and a Glossary of Lean terms. The tools of 5S, value stream mapping, document tagging, continuous flow, standard work, visual control, takt time, pitch, runners, waste, plus numerous other Lean tools are thoroughly defined as well as guidelines provided for the implementation of each tool. This version has digital photos of Lean production best practices throughout!

By: Don Tapping The New Lean Pocket Guide (Chinese Edition) has over 120 illustrations to visually convey the tools and concepts, along with detailed descriptions of all the Lean tools. This newer version of the best selling The Lean Pocket Guide also includes: a section on Lean Office and Six Sigma, 20+ digital photos demonstrating Lean in action, a Waste Audit, and a Glossary of Lean terms. The tools of 5S, value stream mapping, document tagging, continuous flow, standard work, visual control, takt time, pitch, runners, waste, plus numerous other Lean tools are thoroughly defined as well as guidelines provided for the implementation of each tool. This version has digital photos of Lean production best practices throughout! -

By: Debra Hadfield (RN, BSN, MSN), Shelagh Holmes (RN), Tom Fabrizio, Roger Kremer, and Don Tapping

By: Debra Hadfield (RN, BSN, MSN), Shelagh Holmes (RN), Tom Fabrizio, Roger Kremer, and Don Tapping

Note: A Dropbox file link will be provided after purchase and the PDF can be used throughout your organization at no additional charge! This book is the first in the industry to offer real solutions and practical advice for improving patient and non-patient care processes, as well as reducing costs. Included in the book are over 20 forms, worksheets, and guidelines for you to use as a workbook as you implement your 5S portion of a Lean or Six Sigma project. Key learning features of this workbook include: 40+ digital photos demonstrating Lean and 5S projects, identification of who should be doing what part of the 5S activity, detailed procedures ensuring each 5S step is done thoroughly, started tips providing valuable insight from Lean Sensei, and quotes from various leaders throughout the world.