By: Todd Sperl, Joe Buys, and Rob Ptacek

The 5S Training Set allows you to lead a continuous improvement team in the training and the subsequent implementation of 5S. The presentation includes a brief overview of Lean, Six Sigma, and Lean Six Sigma, guidelines for each step, examples from successful 5S practices, as well as Sensei Tips from those who have done it. The worksheets that are referenced can be immediately customized in the accompanying Excel worksheet file. Notes are included throughout the presentation to assist in explaining the various slides.

-

Sale!

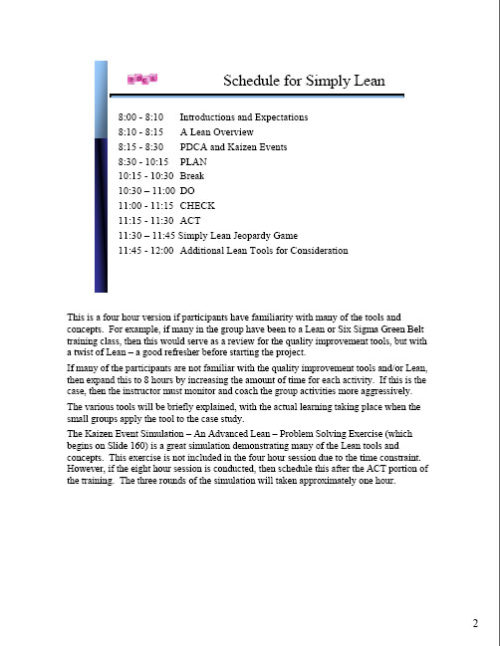

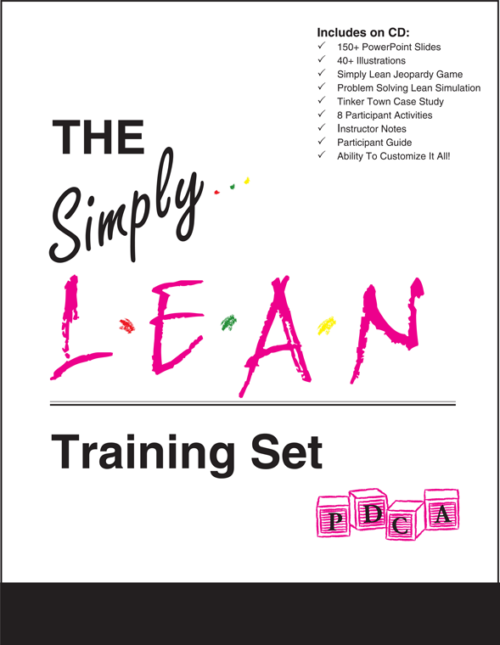

The Simply Lean Training Set is your 21st century solution to conveying the PLAN-DO-CHECK-ACT (PDCA) methodology with a Lean focus. This set is based on over 30 years of problem solving and Lean implementation. The Set allows an organization to teach the topics contained in The Simply Pocket Guide with numerous interactive case studies that allow the participants to practice using basic problem solving tools. The Set also conveys the most basic aspects of Lean through examples and digital photos. In this training set you will learn how to:

The Simply Lean Training Set is your 21st century solution to conveying the PLAN-DO-CHECK-ACT (PDCA) methodology with a Lean focus. This set is based on over 30 years of problem solving and Lean implementation. The Set allows an organization to teach the topics contained in The Simply Pocket Guide with numerous interactive case studies that allow the participants to practice using basic problem solving tools. The Set also conveys the most basic aspects of Lean through examples and digital photos. In this training set you will learn how to:- Use quality improvement tools through case study examples and activities

- Integrate Lean into any problem solving or Six Sigma project

- Conduct Kaizen Events

- Summarize the teachings through a Simply Lean Jeopardy game

- Conduct a simulation that conveys Lean and problem solving solutions

-

Sale!

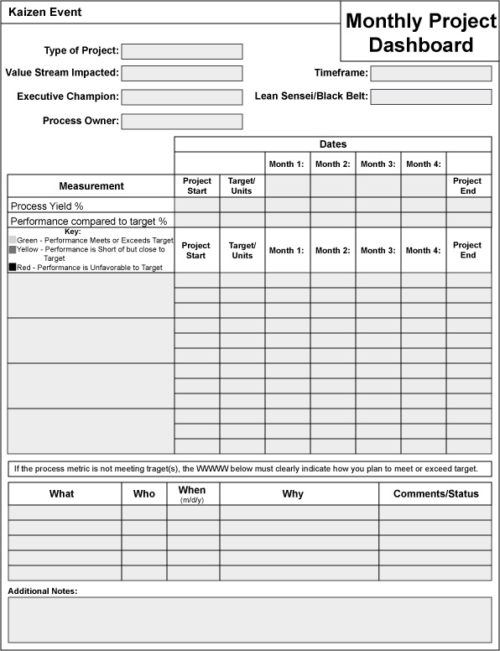

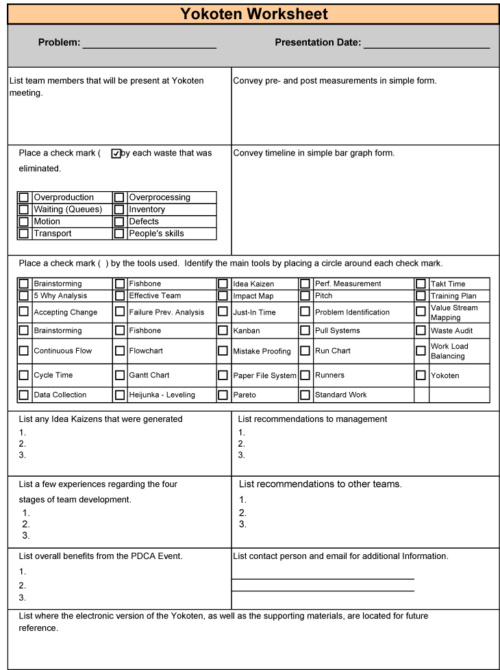

The Kaizen Worksheets include all the forms and checklists you need to conduct a Kaizen event. These are meant to support your internal kaizen event process. For more detail on how to conduct a kaizen event for your industry, please check The Lean Store.com for more workbooks detailing the process. Delivered as customizable Excel worksheets.

The Kaizen Worksheets include all the forms and checklists you need to conduct a Kaizen event. These are meant to support your internal kaizen event process. For more detail on how to conduct a kaizen event for your industry, please check The Lean Store.com for more workbooks detailing the process. Delivered as customizable Excel worksheets. -

Sale!

The Kaizen Demystified Worksheets allow you to customize the tools, concepts, practices, and worksheets demonstrated in the Kaizen Demystified book. These 46 electronic worksheets will allow for an effective and efficient application of engaging people in a Kaizen Event. Delivered as customizable Excel worksheets.

The Kaizen Demystified Worksheets allow you to customize the tools, concepts, practices, and worksheets demonstrated in the Kaizen Demystified book. These 46 electronic worksheets will allow for an effective and efficient application of engaging people in a Kaizen Event. Delivered as customizable Excel worksheets. -

The chart summarizes where specific emerging technologies might be applicable and identifies the chapters from Today's Lean Leader where these technologies are specifically referenced. This is not completely comprehensive as emerging technologies change nearly daily. Leaders must be cognizant of emerging technologies and use them appropriately where they can improve their overall effectiveness, or the effectiveness of the team.

The chart summarizes where specific emerging technologies might be applicable and identifies the chapters from Today's Lean Leader where these technologies are specifically referenced. This is not completely comprehensive as emerging technologies change nearly daily. Leaders must be cognizant of emerging technologies and use them appropriately where they can improve their overall effectiveness, or the effectiveness of the team. -

Sale!

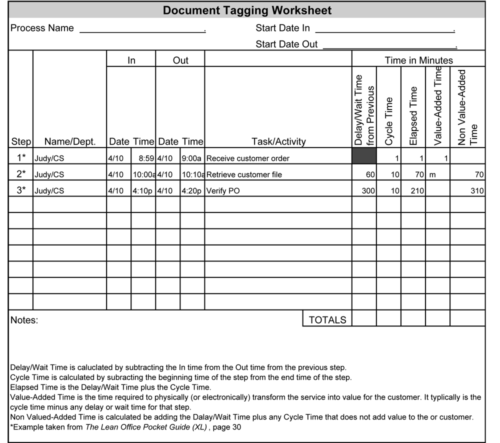

The Simply Lean Kaizen Worksheets allow you to customize the tools, concepts, and practices demonstrated in The Simply Lean Pocket Guide. These 21 electronic worksheets will allow your Kaizen Events to be more effective in communicating the entire process. Delivered as customizable Excel worksheets.

The Simply Lean Kaizen Worksheets allow you to customize the tools, concepts, and practices demonstrated in The Simply Lean Pocket Guide. These 21 electronic worksheets will allow your Kaizen Events to be more effective in communicating the entire process. Delivered as customizable Excel worksheets. -

Sale!

Work load balancing is the optimal distribution of work units throughout the value stream to maintain takt time or pitch. Also known as employee/staff balancing or line balancing, work load balancing assures that now one worker is doing too much or too little work. Work load balancing begins with analyzing the current state of how work relative to the value stream is allocated and ends with an even and fair distribution of work, ensuring that customer demand is met with a continuous flow mentality. The Employee Balance eTool will make this process easier by allowing you to enter the various process activities and cycle times, as well as automatically displaying them in bar graph form. This eTool is a fully customizable Microsoft Excel file. Everything is here and ready for you to get started!

Work load balancing is the optimal distribution of work units throughout the value stream to maintain takt time or pitch. Also known as employee/staff balancing or line balancing, work load balancing assures that now one worker is doing too much or too little work. Work load balancing begins with analyzing the current state of how work relative to the value stream is allocated and ends with an even and fair distribution of work, ensuring that customer demand is met with a continuous flow mentality. The Employee Balance eTool will make this process easier by allowing you to enter the various process activities and cycle times, as well as automatically displaying them in bar graph form. This eTool is a fully customizable Microsoft Excel file. Everything is here and ready for you to get started! -

Sale!

The Lean Desktop Application Assessment allows an individual or group to evaluate current information and data flow relative to Lean concepts and tools. The Assessment is a customizable Microsoft Excel spreadsheet that will serve as a baseline as improvements are made over time, The Lean Desktop Application Assessment should take 5 - 10 minutes for an individual to complete and 30 - 45 minutes for a work group to complete (fill out, not create). Subsequent analysis for the work group may require an additional 1 - 2 hours to plan their first Lean Desktop project from the results of the assessment. The Assessment has 10 main categories that are each linked to an Instruction Sheet that details that particular category as well as to the Overview Sheet (Radar Chart). The score will assist you into allocating the appropriate resources in your Lean Desktop project. The Assessment has 10 main categories of 5S, Quality, Document Management, Visual Controls, Standard Work, Continuous Flow, Email, Leveling, Continuous Improvement, and Digital Waste Training, as well as 34 sub-categories.

The Lean Desktop Application Assessment allows an individual or group to evaluate current information and data flow relative to Lean concepts and tools. The Assessment is a customizable Microsoft Excel spreadsheet that will serve as a baseline as improvements are made over time, The Lean Desktop Application Assessment should take 5 - 10 minutes for an individual to complete and 30 - 45 minutes for a work group to complete (fill out, not create). Subsequent analysis for the work group may require an additional 1 - 2 hours to plan their first Lean Desktop project from the results of the assessment. The Assessment has 10 main categories that are each linked to an Instruction Sheet that details that particular category as well as to the Overview Sheet (Radar Chart). The score will assist you into allocating the appropriate resources in your Lean Desktop project. The Assessment has 10 main categories of 5S, Quality, Document Management, Visual Controls, Standard Work, Continuous Flow, Email, Leveling, Continuous Improvement, and Digital Waste Training, as well as 34 sub-categories. -

Sale!

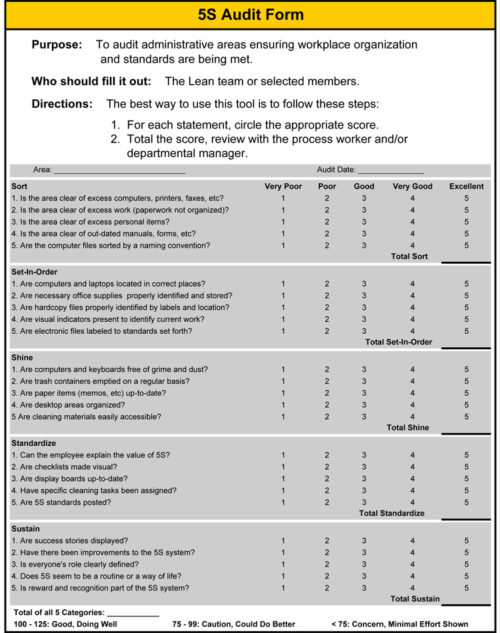

The 5S for the Office User's Guide Worksheets allow you to customize the tools, concepts, practices, and worksheets demonstrated in The 5S for the Office User's Guide. These 41 electronic worksheets will allow for more effective implementation of 5S practices in your administrative areas. Delivered as customizable Excel worksheets.

The 5S for the Office User's Guide Worksheets allow you to customize the tools, concepts, practices, and worksheets demonstrated in The 5S for the Office User's Guide. These 41 electronic worksheets will allow for more effective implementation of 5S practices in your administrative areas. Delivered as customizable Excel worksheets. -

Sale!

The Lean Office Assessment was created allowing a departmental work group or individual to continually assess their Lean or continuous improvement initiatives. The Lean Office Assessment is a customizable Microsoft Excel spreadsheet that will provide a baseline from which you can then improve your administrative processes. It also can assist in determining which Lean tools may be of value during a continuous improvement project. The Lean Office Assessment has 10 Lean building block categories that are further divided into 34 sub-categories that are individually scored. All categories are automatically linked to the Overview page which displays a Radar (or Spider) Chart of the total category scores. The score will assist you into allocating the appropriate resources in your Lean project. When conducting the Assessment the work group or individual must relate their database management procedures and Microsoft Office practices to the overall concepts and tools referenced. The 10 categories are: 5S, Quality, Physical Layout, Visual Controls, Standard Work, Continuous Flow, Pull Systems, Leveling, Continuous Improvement, and Training.

The Lean Office Assessment was created allowing a departmental work group or individual to continually assess their Lean or continuous improvement initiatives. The Lean Office Assessment is a customizable Microsoft Excel spreadsheet that will provide a baseline from which you can then improve your administrative processes. It also can assist in determining which Lean tools may be of value during a continuous improvement project. The Lean Office Assessment has 10 Lean building block categories that are further divided into 34 sub-categories that are individually scored. All categories are automatically linked to the Overview page which displays a Radar (or Spider) Chart of the total category scores. The score will assist you into allocating the appropriate resources in your Lean project. When conducting the Assessment the work group or individual must relate their database management procedures and Microsoft Office practices to the overall concepts and tools referenced. The 10 categories are: 5S, Quality, Physical Layout, Visual Controls, Standard Work, Continuous Flow, Pull Systems, Leveling, Continuous Improvement, and Training. -

Sale!

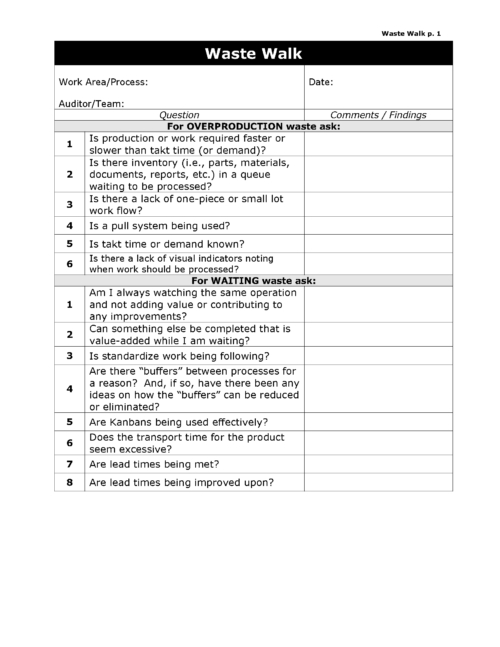

A Waste Walk is an activity for project team members to further understand a process area that is being considered for improvement, asking questions, and then identifying the wastes on the current state value stream or process map. Using this customizable Waste Walk Audit form, the team members, along with their Lean training, can view the area with a fresh perspective as they identify process waste. Delivered as customizable Word document.

A Waste Walk is an activity for project team members to further understand a process area that is being considered for improvement, asking questions, and then identifying the wastes on the current state value stream or process map. Using this customizable Waste Walk Audit form, the team members, along with their Lean training, can view the area with a fresh perspective as they identify process waste. Delivered as customizable Word document. -

Sale!

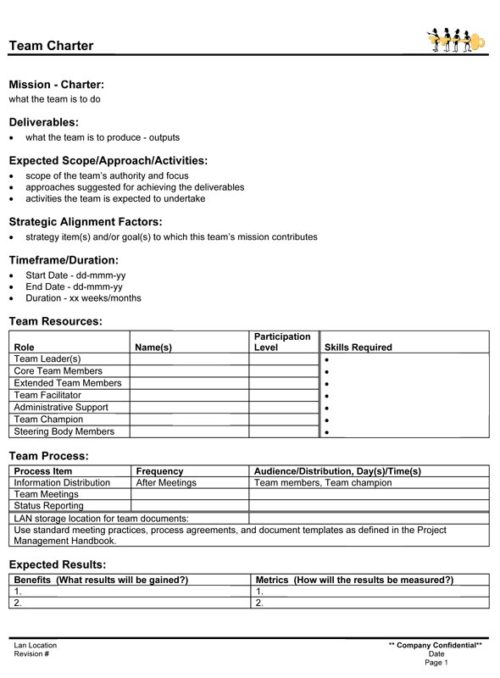

This set of forms has proven successful in many Fortune 500 companies. The key to any project or continuous improvement is effective communications and alignment to the strategic goals of the organization. Delivered as customizable Word documents.

This set of forms has proven successful in many Fortune 500 companies. The key to any project or continuous improvement is effective communications and alignment to the strategic goals of the organization. Delivered as customizable Word documents.