By: Luz Blanco Palma

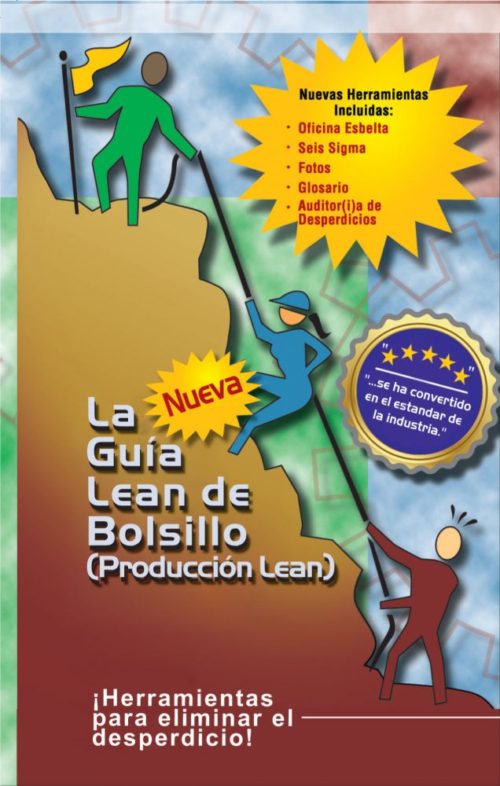

The New Lean Pocket Guide (en Espanól) La Nueva Lean de Bolsillo (Produccion Lean) Refuerze la transformación hacia los procesos esbeltos con La Nueva Guía de Bolsillo (Lean Producción). Este manual ha sido desarrollado tanto para directivos como para empleados, gráficamente explícito, sirve de referencia rápida sobre los procesos de manufacturación esbelta y está optimizado para reducir costos, optimizar la calidad, entregar los productos a tiempo y proveerlo con los conocimientos necesarios para seguir siendo ¡globalmente competitivo en el siglo 21! Esta guía está diseñada para usarla como referencia conveniente y rápida mientras se aprende a implementar la manufactura, tecnología y herramientas esbeltas. Este manual provee de una valiosa visión de los matices del proceso esbelto o lean. ¡Se tiene a mano cualquier aspecto del proceso esbelto en segundos! Y está definitivamente enfocado a las industrias manufactureras. El objetivo principal de esta La Nueva Guía de Bolsillo (Producción Lean) es informar sobre cómo las herramientas de procesos esbeltos pueden ser utilizadas para eliminar cargas y trabajo descartable. Cuanto mejor definido, analizado y resueltos los desperdicios, mejor sera la utilización de estas herramientas en la secuencia apropiada de implementación; por ende mejor será el recorrido del camino hacia la esbeltez globalizada. Indice de Materias - Matriz de Herramientas para Procesos Esbeltos, 5 Eses, Análisis de la Cantidad de Producto (CP) y del Desperdicios y Cargas Descartables, Existencias Acumuladas y de Reserva, Visual, Flujo Continuo, Heijunka (Nivelación de la Carga de Trabajo), Informes y Comunicaciones Esbeltas, Intercambio Rápido, Jidoka, Justo-A-Tiempo, Kanban (Sistema de Arrastre), Layout Celular: Forma de U, Manejo de Herramientas Perecederas, Manejo del la Cadena de Producción, Mantención del Total Productivo, Mapeo de la Cadena de Producción, Metodología para Resolución de Problemas, Métricas de Procesos Esbeltos, Nivelación de la Línea de Producción, Oficina Esbelta (Lean Office), Organigrama, Origen del Proceso Esbelto, Prueba de Errores, Responsable de la Producción, Retiro Pausado, Secuencia para la Implementación del Proceso Esbelto, Seis Sigma (Six Sigma),Talleres Kaizen, Tiempo Cíclico, Tiempo de Ejecución Taka, Tiempo de Retiro del Producto Empacado, Trabajo Estándar, Auditoría de Desperdicios y de Cargas, Glosario.

-

Sale!

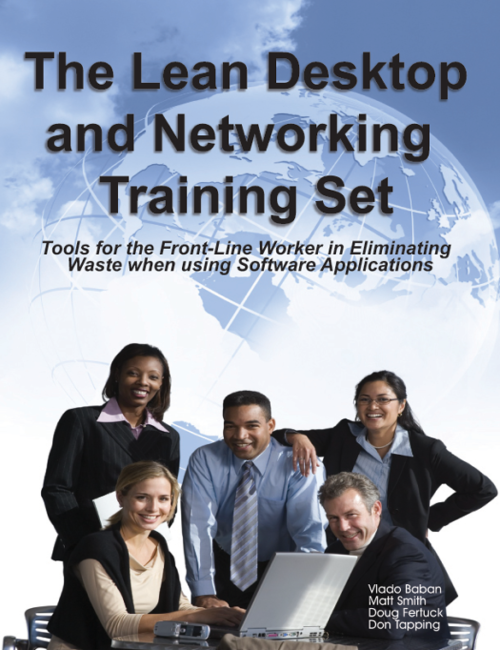

By: Vlado Baban, Doug Fertuck, Matt Smith, Bob Angeli (P.E.), and Don Tapping

By: Vlado Baban, Doug Fertuck, Matt Smith, Bob Angeli (P.E.), and Don Tapping

The Lean Desktop and Networking Pocket Guide XL is designed to be a convenient, quick reference book providing valuable insight into how Lean can be applied to data as it is pulled, analyzed, formatted, and sent through various Desktop and networking applications. The Lean Desktop and Networking Pocket Guide XL details the application of Lean (i.e., the tools and concepts derived from the Toyota Production System), that when leveraged with Microsoft Office and Open Source applications, can assist to better manage data on a daily basis while improving office productivity. Desktop Lean will create a new generation of "power users" and enhance a typical office worker's ability to work individually, as well as collaborate in work group type situations. This "new" power user is a person that readily learns new applications while integrating Lean tools and concepts to eliminate all process waste. -

By: Don Tapping

By: Don Tapping

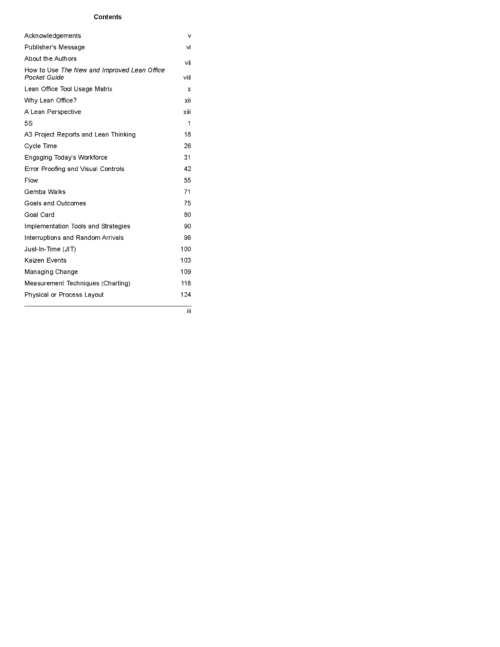

Note: Discontinued! If this product is ordered we will substitute the more comprehensive and up-to-date Practical Lean Six Sigma for Offices (value of $12.95 and is the larger 5" x 8.5" format for easier reading) for the same price for a limited time only. (If quantities over 100 are needed, we can Print-on-Demand, and please email info@theleanstore.com for pricing and availability.)The New and Improved Lean Office Pocket Guide has over 120 illustrations to visually convey the tools and concepts, along with detailed descriptions of all the Lean tools. This newer version of the best selling The Lean Office Pocket Guide also includes: 10 sections that include examples of Lean for electronic files and folders, a Waste Audit, and a Glossary of Lean terms. The tools of 5S, value stream mapping, document tagging, continuous flow, standard work, visual control, takt time, pitch, runners, waste, plus numerous other Lean tools are thoroughly defined as well as guidelines provided for the implementation of each tool. This version has digital photos of Lean office best practices throughout! -

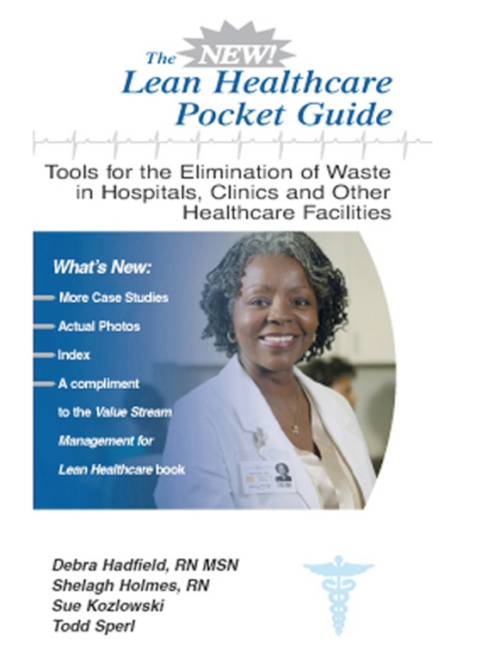

By: Debra Hadfield (RN MSN), Shelagh Holmes (RN), Sue Kozlowski, Todd Sperl, and Don TappingThe New Healthcare Pocket Guide is a collection of input from healthcare professionals and Lean Sensei. It provides easy-to-use and easy-to-understand tools, methods, and concepts based on the world-class Toyota Motor Company (i.e., Lean). The New Lean Healthcare Pocket Guide is design for use as a quick and easy reference as you learn and implement Lean tools. The tools of 5S, continuous flow, cycle time, document tagging, error proofing, goals and outcomes, Just-In-Time, takt time, standard work, pitch, plus all the other Lean tools are thoroughly explained. This “newer” version includes additional case studies, actual photos, an index, as well as compliments the Value Stream Management for Lean Healthcare book. This book will assist any healthcare facility in the enabling them into a Lean environment where the focus is on both driving strategic change and meeting operational goals.

By: Debra Hadfield (RN MSN), Shelagh Holmes (RN), Sue Kozlowski, Todd Sperl, and Don TappingThe New Healthcare Pocket Guide is a collection of input from healthcare professionals and Lean Sensei. It provides easy-to-use and easy-to-understand tools, methods, and concepts based on the world-class Toyota Motor Company (i.e., Lean). The New Lean Healthcare Pocket Guide is design for use as a quick and easy reference as you learn and implement Lean tools. The tools of 5S, continuous flow, cycle time, document tagging, error proofing, goals and outcomes, Just-In-Time, takt time, standard work, pitch, plus all the other Lean tools are thoroughly explained. This “newer” version includes additional case studies, actual photos, an index, as well as compliments the Value Stream Management for Lean Healthcare book. This book will assist any healthcare facility in the enabling them into a Lean environment where the focus is on both driving strategic change and meeting operational goals. -

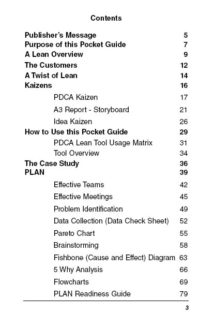

The Lean Pocket Handbook for Kaizen Events is your personal (i.e., individual) Lean planner for the 21st century. We have found individuals that use this pocket handbook feel more part of the Kaizen team. They also continue to contribute improvement ideas well past the formal team Kaizen Event. That is what Lean is all about - making those small, incremental, improvements daily (i.e., hour-by-hour and minute-by-minute) by those closest to the process.This handbook is designed to be:

The Lean Pocket Handbook for Kaizen Events is your personal (i.e., individual) Lean planner for the 21st century. We have found individuals that use this pocket handbook feel more part of the Kaizen team. They also continue to contribute improvement ideas well past the formal team Kaizen Event. That is what Lean is all about - making those small, incremental, improvements daily (i.e., hour-by-hour and minute-by-minute) by those closest to the process.This handbook is designed to be:- A quick-reference guide. Lean tools are explained in more detail in other manuals or by your facilitator during the instruction portion of the workshop.

- Your individual (i.e., personal) log. When working outside the formal training class, notes and ideas about the area or process that are being analyzed can be easily written down in this handbook (serving as your personal log) so as not to lose valuable process information.

- Your personal Kaizen planner. Kaizen Events will require that individual tasks be assigned to team members to be completed prior to the next meeting. Many of these tasks will need to be scheduled within the individual’s current work day. This handbook will thus serve as your “planner” to assure these tasks are adequately planned and completed on time.

- A tool to self-initiate Idea Kaizens. An Idea Kaizen is an individual that implements an improvement with little or no assistance or resource required. This is similar to a Suggestion Program submission; however, the individual with the Idea Kaizen would be responsible for immediate implementation of the idea.

- A learning tool. Each tool will have illustrations to graphically represent the essence of each tool. This will allow you to better understand and learn about each tool prior to using them in your Kaizen Event.

-

First of its kind! The Simply Lean Pocket Guide is the integration of Lean and the PDCA methodology. The interactive Tinker Town case study allows you to take problem solving with a Lean twist to your next performance level. The most basic premise of Lean is to simply and effectively problem solve. The Simply Lean Pocket Guide is a step-by-step approach to the implementation of process improvements using the PDCA model along with a Lean twist. If you are just beginning to adopt Lean or Six Sigma as a business improvement model, whether you are in the healthcare, financial services, construction, armed services, manufacturing, government, logistics, service, or construction industry, the first thing that should be acknowledged is that the solution to the problem (or improvement target that is to be reached) will be found in the intellect of the people who are working the process. Therefore, as a trainer, consultant (internal or external), or departmental head, the focus to improve a situation would be to “somehow” work with that group (and their intellect) and find a solution. However, that “somehow” is not always easy to attain and will require some guidance along the way.

First of its kind! The Simply Lean Pocket Guide is the integration of Lean and the PDCA methodology. The interactive Tinker Town case study allows you to take problem solving with a Lean twist to your next performance level. The most basic premise of Lean is to simply and effectively problem solve. The Simply Lean Pocket Guide is a step-by-step approach to the implementation of process improvements using the PDCA model along with a Lean twist. If you are just beginning to adopt Lean or Six Sigma as a business improvement model, whether you are in the healthcare, financial services, construction, armed services, manufacturing, government, logistics, service, or construction industry, the first thing that should be acknowledged is that the solution to the problem (or improvement target that is to be reached) will be found in the intellect of the people who are working the process. Therefore, as a trainer, consultant (internal or external), or departmental head, the focus to improve a situation would be to “somehow” work with that group (and their intellect) and find a solution. However, that “somehow” is not always easy to attain and will require some guidance along the way. -

Out of stock

First of its kind! The Simply Lean Pocket Guide for Construction is the integration of Lean and the PDCA methodology. The actual case study of Midway Construction demonstrates specifically how problem solving and Lean were used in achieving significant results involving various aspects of the construction industry. The case study - along with the detailed descriptions of the quality improvement tools (with a Lean twist as explained in the case) allows you to take your organization to your next performance level.

First of its kind! The Simply Lean Pocket Guide for Construction is the integration of Lean and the PDCA methodology. The actual case study of Midway Construction demonstrates specifically how problem solving and Lean were used in achieving significant results involving various aspects of the construction industry. The case study - along with the detailed descriptions of the quality improvement tools (with a Lean twist as explained in the case) allows you to take your organization to your next performance level.

NOTE: We are only providing this book as Print On Demand (POD) which requires a minimum order of 100 books. Please call 734-475-4301 to place your order. If you require less than that, please consider The New and Improved Lean Office Pocket Guide or The Simple Lean Pocket Guide.

-

By: Rob Ptacek and Jaideep Motwani (Ph.D.)

By: Rob Ptacek and Jaideep Motwani (Ph.D.)

Today’s Lean! Learning About and Identifying Waste is the first book from the Today’s Lean! series published by MCS Media, Inc. It has been suggested by you, our readers, that you would like Lean and Six Sigma information to be more succinct and at your fingertips, thus allowing for a single tool or concept to be easily accessible (i.e., as a pocket guide and not a manual). Therefore, the Today’s Lean! series of books provide:- Concise content on one main Lean or Six Sigma tool or concept

- Numerous case studies, worksheets, and examples from all types of industries

- Availability as a pocket guide or ebook

- A standard format

- An avenue to update content immediately via your feedback and input (via ebook updates)

- An inspiration for you to implement something similar

-

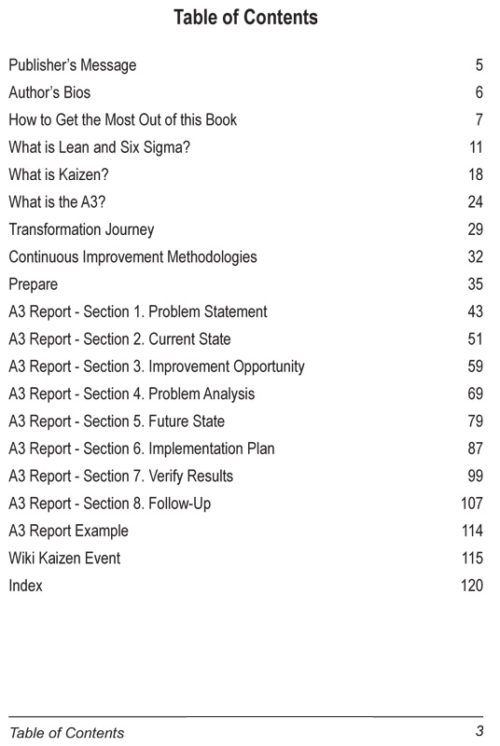

By: Todd Sperl, Rob Ptacek, Jayant Trewn (PhD)The A3 Pocket Handbook for Kaizen Events allows team members to be literally and figuratively on the same page when participating in an improvement event. This allows more ownership, while at the same time preserving organizational knowledge. The improvement methodology used (i.e., Six Sigma D-M-A-I-C, PDCA, etc.) will relate to the A3 Report that is conveyed in this publication. (The A3 Report is designed to help you “tell the story” in a logical and visual way and act as a road map for continuous improvement and problem solving initiatives.) The purpose of this pocket handbook is to:

By: Todd Sperl, Rob Ptacek, Jayant Trewn (PhD)The A3 Pocket Handbook for Kaizen Events allows team members to be literally and figuratively on the same page when participating in an improvement event. This allows more ownership, while at the same time preserving organizational knowledge. The improvement methodology used (i.e., Six Sigma D-M-A-I-C, PDCA, etc.) will relate to the A3 Report that is conveyed in this publication. (The A3 Report is designed to help you “tell the story” in a logical and visual way and act as a road map for continuous improvement and problem solving initiatives.) The purpose of this pocket handbook is to:- Ensure all team members have a quick reference for Lean Six Sigma definitions.

- Compliment, as a mini-workbook, the Practical Lean Six Sigma for Healthcare and The Lean Six Sigma Pocket Guide XL books as well as any other training materials used in an improvement event.

- Provide a road map for continuous improvement projects if no other methodology (i.e., PDCA, D-M-A-I-C, etc.) is used.

- Provide Lean Thinking Statement assessments at the end of each section for employees to “think” Lean and continue their engagement.

- Be a repository of thoughts, ideas, and any action items that may be assigned, etc.

- To retain organizational knowledge by being a personal detailed log of the Kaizen Event to be shared and/or referenced later.

-

By: Roger Kremer

By: Roger Kremer

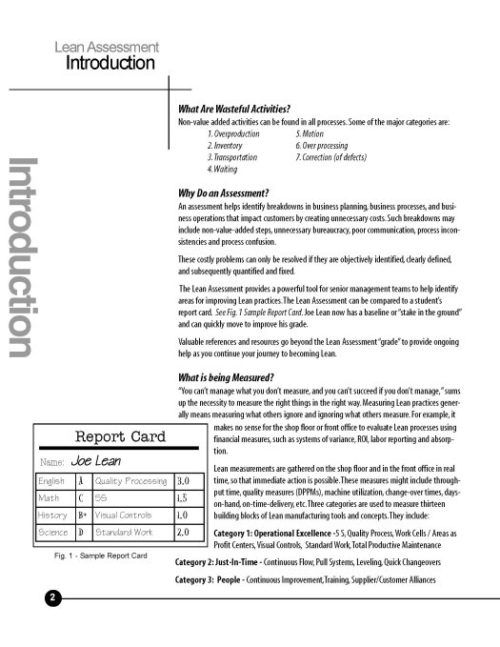

The Lean Assessment was created as a guide to allow the job shop and small manufacturer in their Lean journey. The Lean Assessment will provide a baseline upon which you can improve - and most importantly also provide a reference on what to do. The Lean Assessment has 13 Lean building block categories that are further divided into sub-categories that are scored. The subsequent score will assist you into allocating the appropriate resources in your Lean project. Administrative areas are also referenced in this assessment. The Assessment is self-administering and will allow you to create the necessary visual spider chart to convey the score within the organization. -

By: Don Tapping

By: Don Tapping

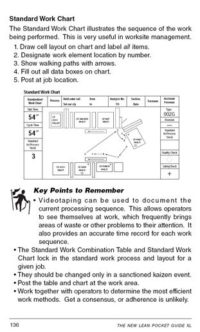

The New Lean Pocket Guide has over 120 illustrations to visually convey the tools and concepts, along with detailed descriptions of all the Lean tools. This newer version of the best selling The Lean Pocket Guide also includes: a section on Lean Office and Six Sigma, 20+ digital photos demonstrating Lean in action, a Waste Audit, and a Glossary of Lean terms. The tools of 5S, value stream mapping, document tagging, continuous flow, standard work, visual control, takt time, pitch, runners, waste, plus numerous other Lean tools are thoroughly defined as well as guidelines provided for the implementation of each tool. This version has digital photos of Lean production best practices throughout!